Mitigating poultry pathogens from flock to fork.

There is nothing more basic to life than a safe food supply. Poultry producers, integrators and processors are dedicated daily to delivering the safest product possible to their consumers. From flock to fork, the industry continues to work together to implement food safety precautions and interventions to fight Salmonella and Campylobacter, the two most common causes of human foodborne illness linked to poultry, along with other foodborne pathogens.

It all starts on the farm. Along with implementing biosecurity and hygiene procedures, producers must manage bird health and reduce shedding of these pathogens in the environment. By controlling Salmonella and Campylobacter on the farm, producers can break the cycle of infection and reinfection, thereby improving the effectiveness of food safety interventions applied in processing.

Poultry producers must control these pathogens while responding to consumer preferences that increasingly demand meat and poultry be produced with less use of antibiotics—or without antibiotics altogether. In-feed strategies to make birds more resilient can help producers control pathogens while meeting demand for antibiotic-free poultry production.

Creating resiliency against pathogens.

The gut is the primary target when animals are exposed to pathogens, causing immunity to falter and leaving birds more susceptible to opportunistic bacteria such as Salmonella spp. That’s why a healthy gut helps make birds more resilient against environmental pathogens. By managing challenges proactively in the gut, producers can reduce pathogen loads, enhance bird health and performance, and, ultimately, reduce the need for antibiotic treatments.

An effective way to achieve these goals is by feeding birds CELMANAX™. The Refined Functional Carbohydrates™ (RFCs™) in CELMANAX work by supporting beneficial bacteria in the animal’s digestive system, while blocking pathogen attachment sites. RFCs act in synergy against gastrointestinal tract (GIT) challenges to consistently improve performance and promote food safety.

Reducing Salmonella in birds and litter.

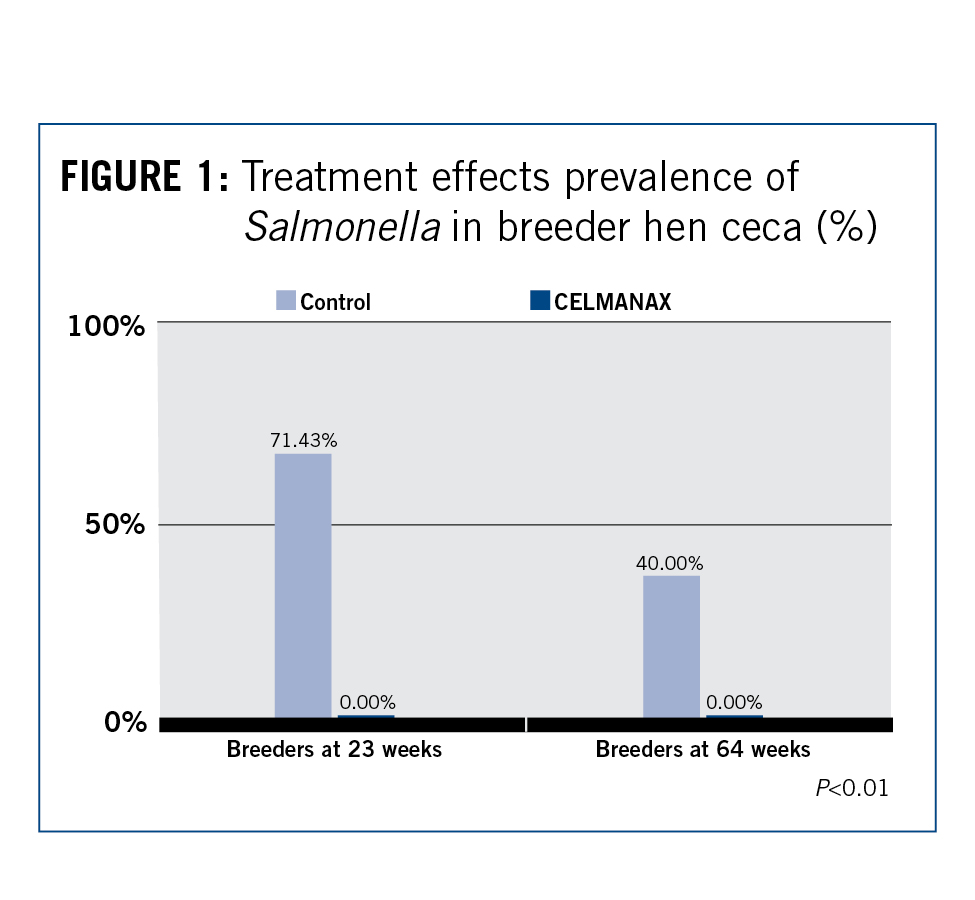

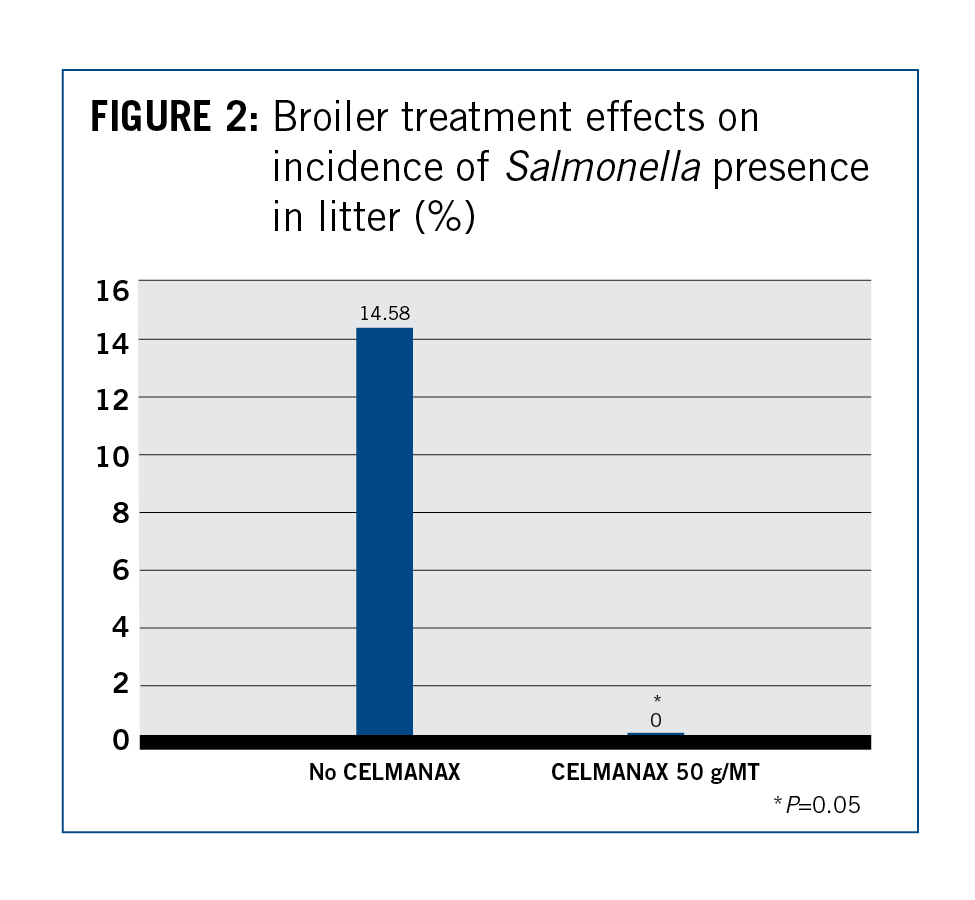

Research trials demonstrate that CELMANAX supplementation can reduce prevalence of Salmonella in birds’ digestive systems and prevent pathogen shedding into poultry litter. Figure 1 shows how feeding CELMANAX reduced Salmonella prevalence in the ceca of broiler breeder hens. In another study, feeding CELMANAX to broilers resulted in lower Salmonella prevalence in litter (Figure 2.)

Reducing Campylobacter risk in poultry.

Like Salmonella, Campylobacter spp. are major concerns in both live poultry operations and processing plants. Although generally non-pathogenic in birds, Campylobacter jejuni can cause human enterocolitis through consumption of undercooked meat that is contaminated with the organism.

Researchers studied the effect of CELMANAX on C. jejuni colonization in broiler and turkey ceca. Trial results showed that birds fed a CELMANAX diet had lower prevalence of C. jejuni in ceca.

Conclusion.

Research supports the benefits of CELMANAX as part of a multifactorial pathogen mitigation strategy in poultry production. Feeding CELMANAX helps reduce the presence of Salmonella and Campylobacter on the farm, supporting food safety interventions needed to protect consumer confidence in the food supply.

READY TO LEARN MORE?Want to learn more about what our #ScienceHearted team can do for your operation? Fill out the form below and one of our experts will be in touch shortly. |

About Dr. Sangita Jalukar |

|

Dr. Sangita Jalukar has extensive experience across the poultry production industry. She currently serves as a senior technical services manager at ARM & HAMMER™ where she is involved in the development of new products, conducting multi-species research trials and providing technical assistance to the field sales teams. Dr. Jalukar received her B.S., M.S. and Ph.D. degrees from Maharaja Sayajirao University in Baroda, India, and earned a post-doctoral fellowship from the University of Iowa. |