Controlling manure odors with microbial feed additives.

Odors have always been a natural part of any hog farm’s daily operation. It seems like a small price to pay for all the joy bacon delivers, but as urban sprawl continues closer and closer to farmland, it’s an obstacle we must continue to combat. Despite Right to Farm laws that work to protect American agriculture in almost every state, hog farm nuisance lawsuits are a serious threat to business—and are setting dangerous precedents.

$473.5 million was awarded to the neighbors of a hog farm in North Carolina over “the obnoxious, recurrent odors and other causes of nuisance.” While limits under the state law reduced the total owed to $94 million, the precedent was clear. Consumers, including juries, neighbors and shoppers, have high expectations of us in the swine industry. More innovation. More meat produced with fewer resources and technologies. And more solutions to lessen environmental impact, including odors and pollution.

Hog farm odor regulations.

These pressures are mounting globally, and in the U.S. almost every state has regulations that limit odors from animal feeding operations. Knowing your state’s standards can help you stay ahead of disputes and, worst case, lawsuits. While most are indirect regulations, they include several methods that affect hog farmers.

- Setbacks.

Defined as the minimum distance from a property line that a building can be erected, setbacks range from 50 ft. to 16,000 ft. and are present in 20 states. They differ based on source type, type of receptor and size of the farm.

- Permits.

One of the most common regulations, registering your operation or obtaining some other type permit is required in 41 states.

- Public comment periods.

21 states allow some type of public involvement, while several have enacted public comment periods.

- Operator training.

In 15 states, owners and operators applying manure must have proper training.

- Land application training.

Similarly, 20 states require training on when, where and how to apply manure to the land.

What causes manure odors?

Volatile Fatty Acids (VFAs) include the odor-causing compounds associated with swine manure. Acetate, Propionate, Butyrate and Iso-Valerate make up the VFAs that are most important to control.

Your manure management plan.

Taking all the steps you can to stay environmentally friendly is one of the best ways to protect your business, starting with a thorough review of your manure management plan. While there are several ways to reduce odors from your hog farm, they range in efficacy and economic viability.

Diet modifications.

For years, producers have tried to reduce odors by formulating hogs’ diets to minimize excess nutrients. Cutting crude protein levels and increasing crystalline amino acids can successfully reduce odors by reducing nitrogen excretion. However, it can be difficult to manage nutrients in the pit as ration ingredients change due to fluctuating commodity prices.

A more advanced way to control odors is by harnessing the microbial populations that break down manure solids in the pit. Most manure odors are caused by improper fermentation and an imbalance of bacteria in the storage system that leads to accumulation of VFAs.

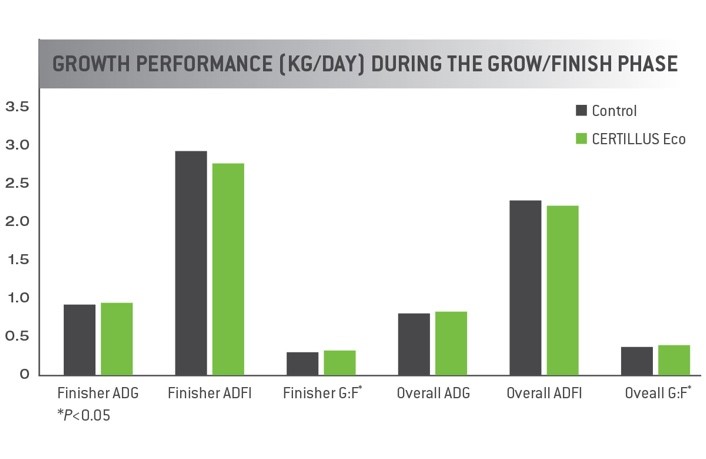

Feeding CERTILLUS™ Eco to pigs delivers beneficial bacteria directly to the pit through the manure. By improving microbial fermentation of manure, CERTILLUS Eco reduces odor-causing VFAs and improves fertilizer value of manure, all while improving feed efficiency by 5% in the finisher phase and 3% overall.

Unlike pit additive alternatives that require agitation and mixing to distribute within the storage system, CERTILLUS Eco is already evenly distributed in the manure itself. Plus, CERTILLUS Eco reduces viscosity of manure for easier removal and pumping.

Manure injection.

Injecting manure below the soil surface instead of broadcasting it can greatly reduce odors. In most states, producers will need to incorporate this as part of their nutrient management plan as it also helps prevent run-off and erosion. The thinner the manure, the easier it is to pump and inject—so by improving viscosity, CERTILLUS Eco may also aid manure injection.

Cover it up.

Permeable and impermeable covers help prevent gases from escaping your manure storage. Straw, cornstalks and geotextiles can reduce odors by 40-50% and cost up to $0.25/sq. ft. Impermeable covers like high-density polyethylene show greater reduction in odors but cost in the $1-1.40/sq. ft. range and require snow and rain accumulation management. Additionally, masking agents added to the pit may hide odor symptoms but do not address the true problem of microbial fermentation failure.

Start today.

Reducing the odors from the manure pits on your hog farm has become a necessity as pig productivity and consumers’ environmental concerns have increased simultaneously. For a personalized recommendation on how to solve your farm’s challenges, contact the Swine Team at ARM & HAMMER™.

READY TO LEARN MORE?Want to learn more about what our #ScienceHearted team can do for your operation? Fill out the form below and one of our experts will be in touch shortly. |